University of Maryland Professors S.K. Gupta (ME/ISR) and Hugh Bruck (ME) and their students have developed and demonstrated a new robotic bird, “Robo Raven,” whose wings flap completely independently of each other, and also can be programmed to perform any desired motion, enabling the bird to perform aerobatic maneuvers. This is the first time a robotic bird with these capabilities has been built and successfully flown.

What makes building robotic birds so difficult? Not only is there a long trial and error process, but every error leads to a crash, often one that is fatal to the robot. This makes design iterations painfully slow.

Gupta, a professor in Mechanical Engineering and the Institute for Systems Research in the A. James Clark School of Engineering, has been working on flapping-wing robotic birds for the better part of a decade. He and his graduate students, along with Mechanical Engineering Professor Hugh Bruck, first successfully demonstrated a flapping-wing bird in 2007. This bird used one motor to flap both wings together in simple motions. By 2010 the design had evolved over four successive models. The final bird in the series was able to carry a tiny video camera, could be launched from a ground robot, and could fly in winds up to 10 mph—important breakthroughs for robotic micro air vehicles that one day could be used for reconnaissance and surveillance. It even fooled a local hawk, which attacked the robot in mid-flight on more than one occasion.

Gupta, a professor in Mechanical Engineering and the Institute for Systems Research in the A. James Clark School of Engineering, has been working on flapping-wing robotic birds for the better part of a decade. He and his graduate students, along with Mechanical Engineering Professor Hugh Bruck, first successfully demonstrated a flapping-wing bird in 2007. This bird used one motor to flap both wings together in simple motions. By 2010 the design had evolved over four successive models. The final bird in the series was able to carry a tiny video camera, could be launched from a ground robot, and could fly in winds up to 10 mph—important breakthroughs for robotic micro air vehicles that one day could be used for reconnaissance and surveillance. It even fooled a local hawk, which attacked the robot in mid-flight on more than one occasion.

But the limitation of simultaneous wing flapping restricted how well the robotic bird could fly. So Gupta decided to tackle the much thornier problem of creating a more versatile bird with wings that operated independently, just like real birds. An unsuccessful attempt in 2008 led to the project being shelved for a while. Then, in 2012, Gupta partnered with Bruck and their graduate students to try again.

“Our new robot, Robo Raven, is based on a fundamentally new design concept,” Gupta says. “It uses two programmable motors that can be synchronized electronically to coordinate motion between the wings.”

The challenge was that the two actuators required a bigger battery and an on-board micro controller, which initially made Robo Raven too heavy to fly.

“How did we get Robo Raven to ‘diet’ and lose weight?” Gupta asks. “We used advanced manufacturing processes such as 3D printing and laser cutting to create lightweight polymer parts.”

But smarter manufacturing and lighter parts were only part of the solution.

So the team did three more things to get Robo Raven airborne. They programmed motion profiles that ensured wings maintained optimal velocity while flapping to achieve the right balance between lift and thrust. They developed a way to measure aerodynamic forces generated during the flapping cycle, enabling them to evaluate a range of wing designs and quickly select the best one. Finally, the team performed system-level optimization to make sure all components worked well together and provided peak performance as an integrated system.

“We can now program any desired motion patterns for the wings,” Gupta says. “This allows us to try new in-flight aerobatics—like diving and rolling—that would have not been possible before, and brings us a big step closer to faithfully reproducing the way real birds fly.”

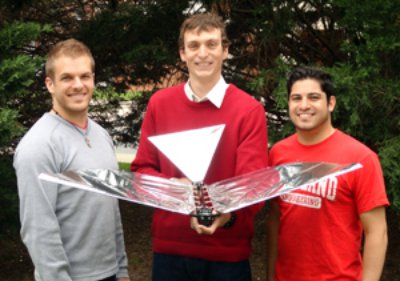

Photo: (L-R) Students Luke Roberts, John Gerdes, and Ariel Perez-Rosado with Robo Raven -University of Maryland.

Source: University of Maryland

This is not the first one as the ROBIRD from Clearflight Solutions has already been developed and tested. It is now at tested at Schiphol airport for bird control. It also only used it wings and no additional propulsion systems to fly.

http://www.clearflightsolutions.com