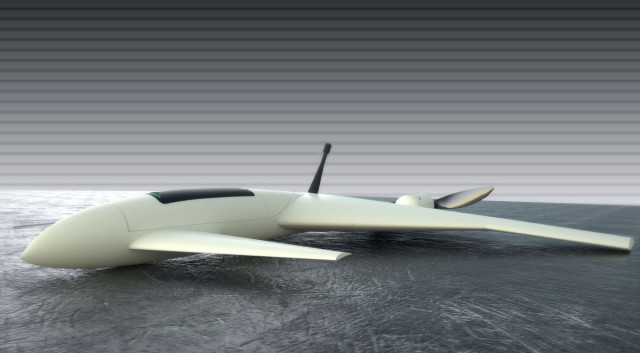

, an unmanned aircraft systems (UAS) research and manufacturing company based in Singapore has launched the Captor UAS. The first commercially available fully 3D printed drone, the Captor UAS is designed to be completely modular to adapt and grow with the changing demands and requirements of each customer – bringing future proof technology to the end-user and protecting initial investments.

First announced in May 2015, O’Qualia has since conducted extensive market research amongst small business owners, government institutions and communities of UAS enthusiasts, anticipating the use-case scenarios and potential challenges in the daily applications of an aerial imaging solution. The bigger 2-meter wingspan Captor XV is now slated for partnerships with government linked technology and research groups.

Alluding to the concept of the well-known multi-purpose tool the Dremel, Head of Product Innovation, Elias Moseer states, “Captor is the platform to build a high level of familiarity with drones and at the same time it evolves as one’s demands grow. Just as various parts can be rotated and added to a Dremel to expand on its functionality and usage, Captor empowers each user to dictate how far or fast the product can be diversified to address different needs as they happen.”

“It will be phenomenal to imagine what our end users can do or add to the plate, and we have already progressed this far based on these insights and will continue to evolve.”

Designed in 4 aerodynamic and streamlined sections, the individual components were optimally segregated to ensure the toughest resilience for each 3D printed part. Spares can be reprinted by end-users themselves or ordered from O’Qualia at rates well below available 3D printing providers. In addition, the 4 sections can be assembled and disassembled quickly in the field, making it highly responsive to environment or application changes.

“With aerial imaging sensors becoming smaller and more advanced every day, one should not be tied to a particular sensor, but should be able to experiment and exchange sensors easily without needing to overhaul complete systems or be sensor integrator experts.” Moseer adds.

Measuring 800mm in wingspan, the Captor UAS is able to carry up to 450g of payload, which is well above most payload weights currently used in the market. Assembled in a stringently precise click mechanism, the airframe and payload compartment can be easily secured in a highly durable manner. A series of stress tests were conducted including application of blunt and short distance momentum force to the airframe and parts demonstrating the resilience of the key components. Inspired by single-bead 3D printing techniques, the key contributing factor lay in the design of skin and internal framing whose structure was stiff enough to withstand force and yet light enough to be power optimal.

O’Qualia is now in progress of collaborating with leading local 3D printing service providers to extend affordable reprinting in the very near pipeline on an international level. Captor UAS is now available for limited pre-orders at US$ 2750, while regular pricing ranges from US$ 5000 up to US$ 14000 depending on initial configuration.

Source: Press Release