a GE Venture, is partnering with NVIDIA to use some of the latest advances in artificial intelligence computing to optimise the use of robotics for inspection and better detect defects on industrial assets with advanced data analytics.

Avitas Systems can target specific points of inspection and develop paths to collect data in the form of images and video for a variety of robotics, including drones, robotic crawlers, and autonomous underwater vehicles (AUV). These paths, driven by 3D models, can be repeated from the same angles and locations. The paths’ repeatability means a wide variety of images captured over time can be inputted into the Avitas Systems cloud-based platform, so advanced image analytics can detect changes and measure exact defects on an industrial asset, such as cracks and corrosion.

The platform can also rate the severity of defects, oftentimes not visible to the human eye, allowing customers to determine when equipment needs to be replaced and enabling earlier resolution of potential issues.

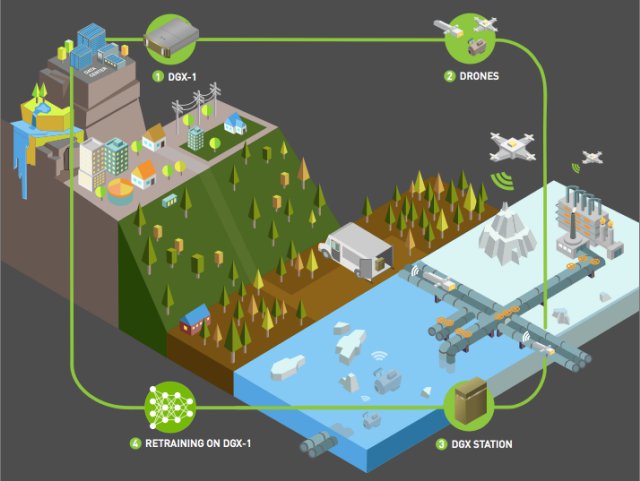

The company is using NVIDIA DGX-1 and DGX Station systems for AI training involved in automated defect recognition. Avitas Systems data scientists build convolutional neural networks for image classification and generative adversarial neural networks to minimise the amount of work involved in labelling captured images. NVIDIA allows Avitas Systems to train software to process many different images and determine when it is ready to identify defects, following a variety of models.

Avitas Systems stores deep learning models in an AI Workbench, an innovative solution that can process inspection data in real-time and retrain the models to adapt to new use cases.

“Working with NVIDIA allows us to fully commercialize our cutting-edge, self-service AI Workbench, and we look forward to expanding its capabilities using the new NVIDIA DGX Stations with Volta,” said Alex Tepper, Founder and Head of Corporate and Business Development at Avitas Systems. “With our workbench, our engineers can easily create and access new deep learning models that train the software deployed to recognize defects automatically at inspection sites.

Avitas Systems uses global expertise to push the boundaries of AI and inspection services.

“Avitas Systems is breaking new ground by bringing NVIDIA DGX Station beyond the deskside and into the field for the first time,” said Jim McHugh, General Manager of DGX Systems for NVIDIA. “Using our latest DGX systems to help train robots and better predict industrial defects increases worker safety, protects the environment, and leads to substantial cost savings for companies.”

Full infographic explaining the system is available here.

Source: Press Release

How come you have used the picture of our product in this article without authorisation ? HL48 Skyhorse ?!

Stephen,

This photo was part of a press release – if you click on the link in the post to the infographic you will find back the photo on the Nvidia website…