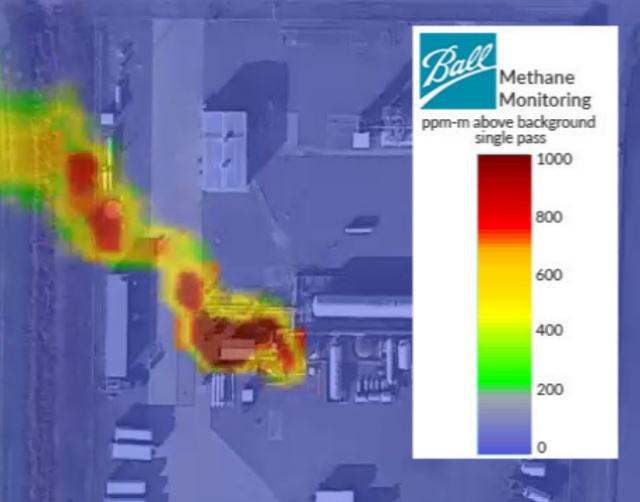

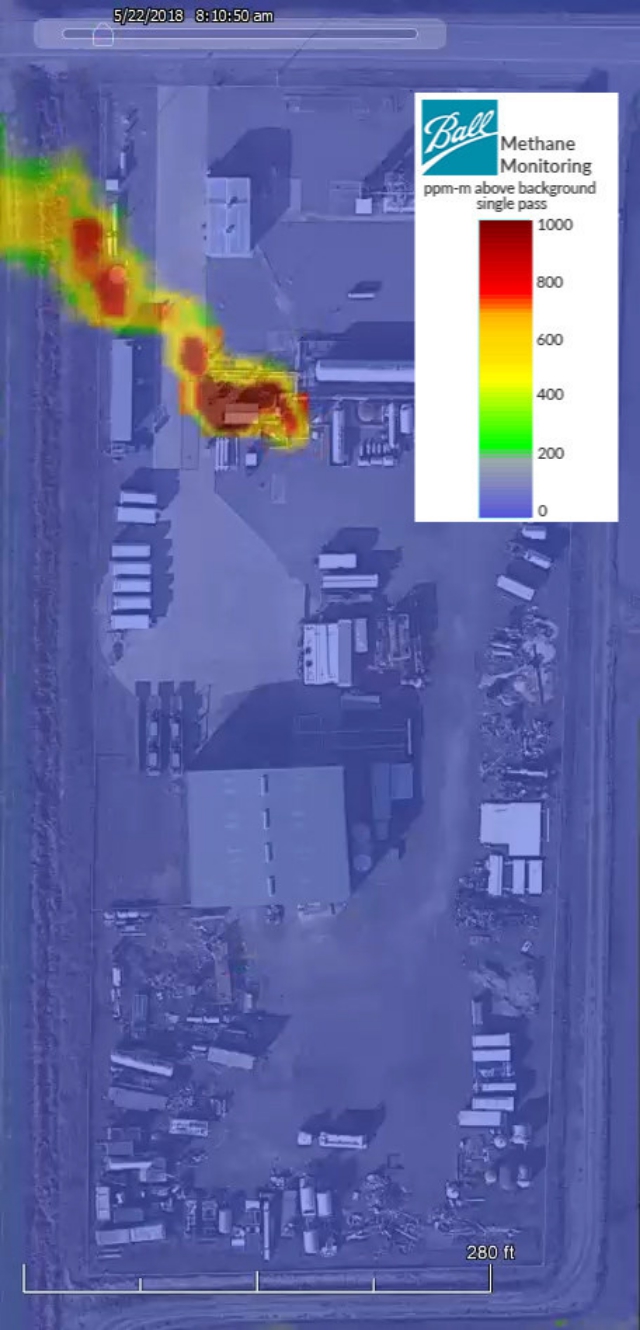

demonstrated its methane remote sensing technology flying on board a piloted aircraft during the Stanford University and Environmental Defense Fund (EDF) Mobile Monitoring Challenge, resulting in high-resolution, geo-referenced imagery of simulated methane leaks in near real-time.The Mobile Monitoring Challenge is a new competition co-sponsored by Stanford University’s Natural Gas Initiative and the EDF that involves select teams that take part in a single-partial blind study of controlled methane releases over a three-week period in May.

“Ball has been testing and conducting pilot trials of its Methane Monitor technology with end users for the past 18 months,” said Brad Tousley, vice president, Commercial Aerospace and Strategic Technology, Ball Aerospace. “With an excellent leak detection threshold and wide-area survey capability, our Methane Monitor enables operators to map entire infrastructures with extreme sensitivity to find and source individual leaks.”

During the challenge, the Ball Methane Monitor was flown on a twin-engine aircraft flying at 125 miles per hour at an altitude of up to 3,500 feet. This rapid and long-range flight enables an efficient, accurate and cost-effective survey of widely dispersed facilities without the speed and range limitations of today’s unmanned aerial vehicles or ground-based mobile systems. Initial results were returned to the Stanford and EDF test conductors within 6 hours after flight, with a full report delivered within 24 hours.

Leveraging Ball’s more than 30 years of experience developing proven laser technologies, the Methane Monitor uses active laser spectroscopy techniques to identify atmospheric methane. With this remote sensing technology, Ball can gather excellent spatial resolution column measurements down to 50 ppm-m of methane above background and deliver rapid results to enable visual assessment of leak sources. An individual sensor allows for daily surveillance of up to 100 square miles of oil and gas production regions, or 375 miles of transmission pipeline.

The Ball Methane Monitor has multiple applications, including enabling safety evaluations of pipeline operations as well as offering a cost-effective commercial technology capable of rapidly monitoring large areas of oil and gas production facilities and miles of pipeline to detect methane leaks.

Source: Press Release