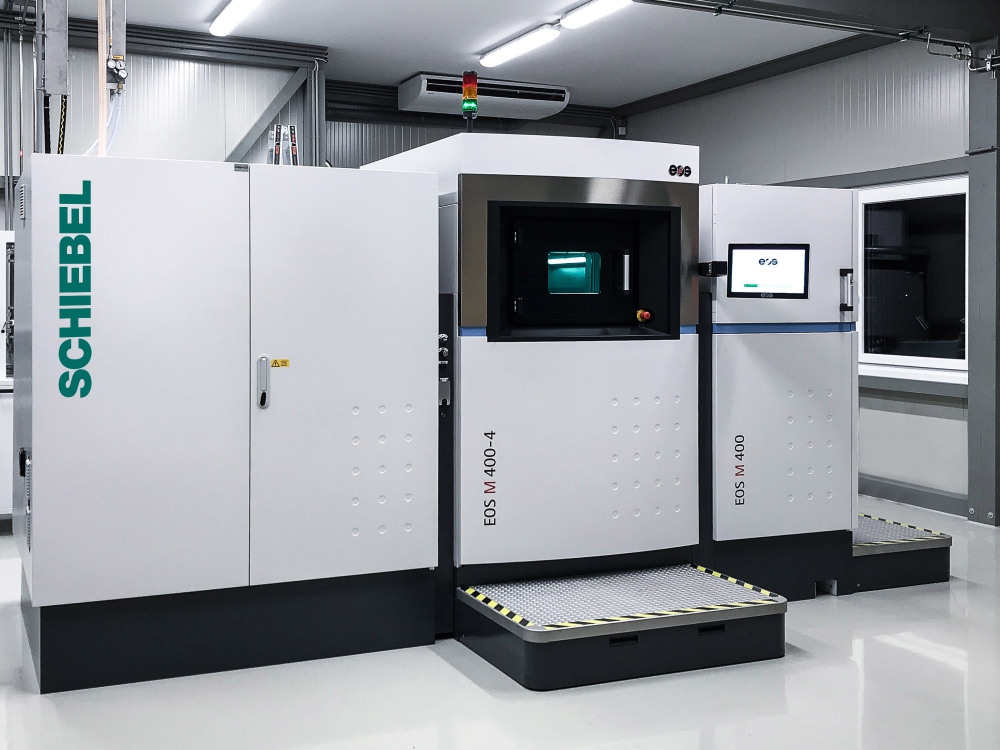

Schiebel further enhances its production capabilities by investing in a state-of-the-art EOS M 400-4 metal 3D printer for additive manufacturing.

Schiebel continuously develops its CAMCOPTER S-100 Unmanned Air System (UAS) by integrating the latest technologies and further improving its production capabilities. Schiebel’s new 3D printer is being utilised to produce complex titanium components of the S-100 even more effectively, increasing design freedom and enabling valuable weight savings.

The 3D printer is being operated at Schiebel’s flagship production facility in Wiener Neustadt, Austria. The facility is currently being doubled in size to meet the growing demand for Schiebel’s market-leading CAMCOPTER S-100 UAS and is set to be completed mid-2020.

Hans Georg Schiebel, Chairman of the Schiebel Group, said:

“Schiebel prides itself on always being at the edge of aerial innovation. Being able to make use of additive manufacturing opens a plethora of opportunities to further develop the CAMCOPTER S-100. Every future gram we save on the aircraft allows us to further increase endurance or payload capacity.”

Source: Press Release