Alpha knows that reliability improves “minute-by-minute,” – Madrid based Alpha Unmanned System, SL announced that its High Accelerated Lifetime Testing (HALT) solution is now in production.

This means that Alpha’s engines and transmissions will be tested in “near-flight” environments for significantly longer periods of time and in environments more similar to actual flight. Longer and more realistic testing means greater fault identification which will result in more reliable platform design and manufacture.

The HALT will also be used to define the maintenance periods of Alpha’s new helicopter platform, (expected in H2Y20). It will also be used to execute the STANAG defined engine endurance tests and to fine-tune the fuel injection system.

“Testing is critical for flight reliability and safety. The incorporation of the HALT will dramatically increase the testing hours that Alpha Engineers can use to improve design and manufacturing. We expect to dramatically improve our platform quality and reliability through this innovative and necessary tool,” states Álvaro Escarpenter, CTO and co-founder of Alpha.

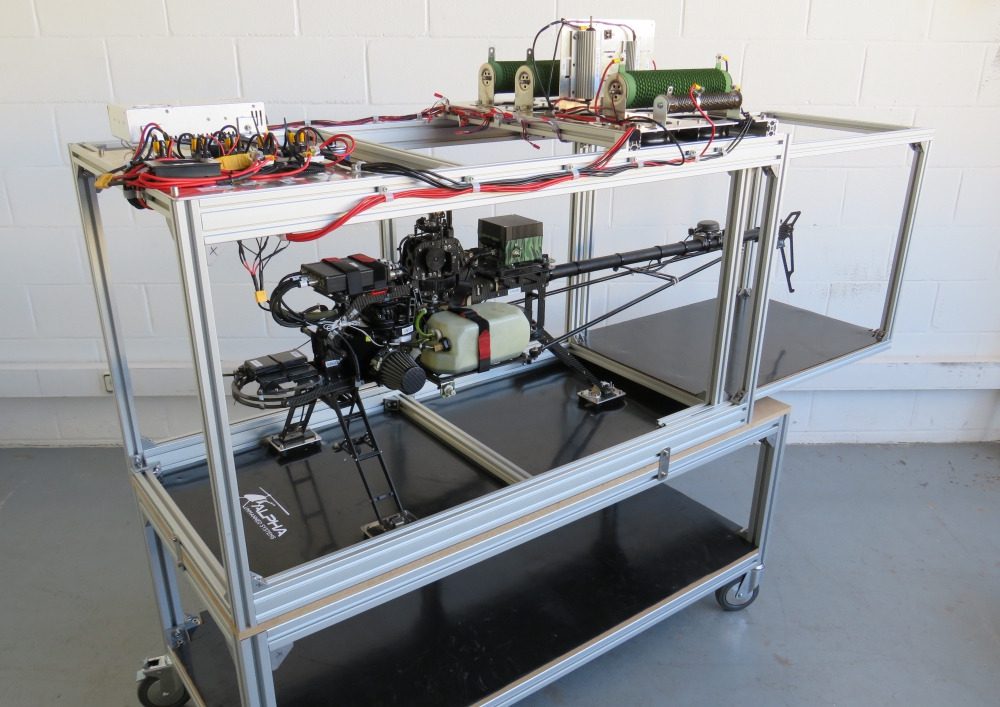

In order to easily test the complete helicopter, including the engine and transmission systems, Alpha has designed and manufactured its own test bench (HALT) on which its helicopters will be able to test multiple engine and transmission loads in a precisely controlled environment. The HALT will also simulate endurance and life cycle tests in “near-flight” conditions.

Engine and transmission systems are especially critical for helicopter platforms. Since testing and validation exercises are time consuming and costly, and since industrial systems must be tested for thousands of cycles during development, Alpha’s expects to dramatically improve the airworthiness of its helicopter UAV platforms using HALT.

Source: Press Release