‘s Marine Products division has signed an MOU with Singapore-based drone delivery provider F-drones, for last mile delivery of its 3D printed spare parts.

As the only drone delivery provider currently authorized by the Civil Aviation Authority of Singapore (CAAS) to execute drone deliveries Beyond-Visual-Line-of-Sight (BVLOS) to vessels at anchorage, the agreement with F-drones enables Wilhelmsen to broaden the scope of its exclusive on-demand additive manufacturing service.

Hakon Ellekjaer, Head of Venture, 3D Printing, Wilhelmsen says,

“Exploring safe, reliable and inexpensive alternatives for last mile delivery of our 3D printed parts to our customers is key for us moving forward. F-Drones is actively developing a solution and their ambitions are very much aligned with our own, to disrupt the existing supply chain and offer a service that is faster, cheaper and greener”.

Currently refining the next iteration of its own proprietary drone system, capable of carrying 5kg over a distance of 50km, F-drones’ long-term ambition is to develop a larger scale drone capable of delivering 100 kg to vessels up to 100 km away.

Commenting on the agreement, Yeshwanth Reddy, Co-founder of F-drones, says,

“We are excited to be working together with Wilhelmsen’s 3D printing venture, which is at the forefront of commercializing on-demand manufacturing for the maritime industry. Its capability can provide a large variety of parts in different shapes, sizes, and materials. With our drones that can carry much bigger items over longer distances, we can catalyze the adoption of on-demand printing of parts for the maritime industry”.

As part of an exclusive Early Adopter Program for 3D printed marine spare parts, 6 customers signed up with Wilhelmsen’s Marine Products division in December 2019 to begin utilizing on-demand additive manufacturing. Existing customers include Berge Bulk, Carnival Maritime, Thome Ship Management, OSM Maritime Group, Executive Ship Management and Wilhelmsen Ship Management.

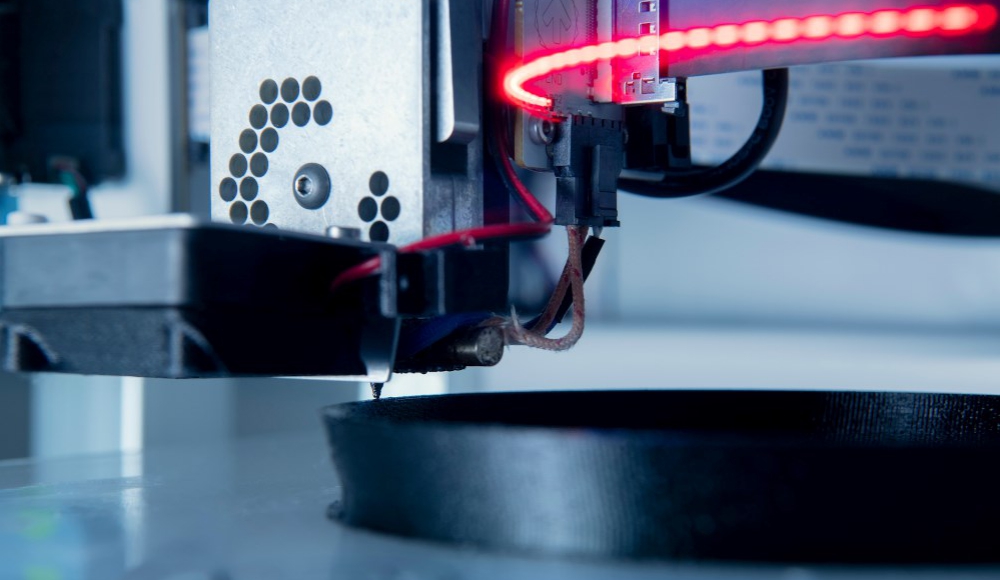

Wilhelmsen is providing 3D printed spare parts on demand to the selected six customers’ vessels around the globe, reducing the typically high supply chain costs, long lead times and impact on the environment associated with the traditional supply chain. Through a unique selection, digitization, and documentation process, parts are produced on-demand, without having to go through time consuming and costly storage, shipping, customs and receiving processes.

Source: Press Release