Following a rigorous, five-week series of structural proof tests of the jet’s airframe, the US Navy /Northrop Grumman test team have proven that the X-47B Unmanned Combat Air System will be able to withstand all of the structural stresses and strains associated with takeoff, flight and landing – including those uniquely linked with landing or taking off from the moving, pitching deck of an aircraft carrier.

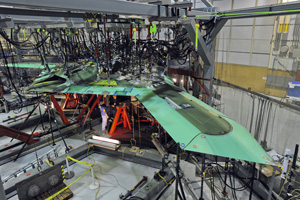

The tests on X-47B air vehicle 2 (AV-2), conducted at Northrop Grumman’s X-47B assembly and test facility in Palmdale, were completed Jan. 24, one week ahead of schedule. Northrop Grumman is the Navy’s prime contractor for the Unmanned Combat Air System – Demonstration (UCAS-D) programme.

“The proof tests validate the structural design of the aircraft, and give us confidence that we can operate this plane safely and reliably in all anticipated carrier environments,” said Janis Pamiljans, vice president of the Navy UCAS programme for Northrop Grumman’s Aerospace Systems sector. “In particular, we now know that AV-2 can handle the stresses, strains and dynamic loads associated with catapult launches and arrested landings on the carrier deck, and air-to-air refuelling.”

AV-2 is identical to the first X-47B UCAS demonstration aircraft (AV-1) – which successfully completed its historic 29-minute first flight at Edwards Air Force Base, Calif. on Feb. 4 – except that it will be equipped with aerial refuelling equipment. Northrop Grumman plans to use AV-2 to demonstrate unmanned air-to-air refuelling – using both the U.S. Air Force’s boom/receptacle approach and the Navy’s probe and drogue approach – in 2014 as part of a technology demonstration related to the current UCAS-D contract.

The proof testing performed on AV-2 simulated eight design conditions, such as a 3-G symmetrical pull up and a 2.4G rolling pullout; and five conditions expected to occur on the ground, including takeoff and landing, said Sarah Beaudin, Northrop Grumman’s AV-2 manager.

One of the ground tests included pulling on the nose gear (to simulate a catapult launch) and the tail hook (to simulate an arrested landing on the carrier deck) at the same time to provide a special combined load case for test with the required margins. One of the flight conditions simulated the forces produced by turbulence that could occur during air-to-air refueling, a more demanding requirement than that used to proof test AV-1 in 2009.

“To perform the testing, we bonded pads to 200 points on the airframe surface, and then pushed and pulled on those pads using hydraulic jacks to simulate various static and dynamic load conditions,” explained Beaudin. “By measuring the stresses and strains experienced by the airframe in this test environment, we’ll also be able to measure and interpret more accurately the stresses and strains experienced during flight.”

Proof testing is one of the last few tests that AV-2 will undergo in Palmdale before its transition later this spring to Edwards Air Force Base for more system tests, taxi tests and first flight. Before that move occurs, the test team plans to test and calibrate the aircraft’s fuel system, and paint the aircraft.

Source: Northrop Grumman